Root Cause Analysis (RCA) in Lean Six Sigma

Using 5 Whys and Fishbone (Ishikawa) Diagram

What is Root Cause Analysis (RCA)?

Root Cause Analysis is a structured problem-solving approach used in Lean Six Sigma to identify the real cause of a problem—not just its symptoms.

Goal: Fix the problem once and permanently, not repeatedly.

RCA is mainly used in the Analyze phase of DMAIC.

Why RCA is Critical in Lean Six Sigma

Prevents recurring defects

Avoids “quick fixes”

Reduces waste and rework

Enables sustainable improvement

Supports data-driven decisions

Two Most Powerful RCA Tools

Lean Six Sigma commonly uses:

5 Whys

Fishbone (Cause-and-Effect) Diagram

They are often used together.

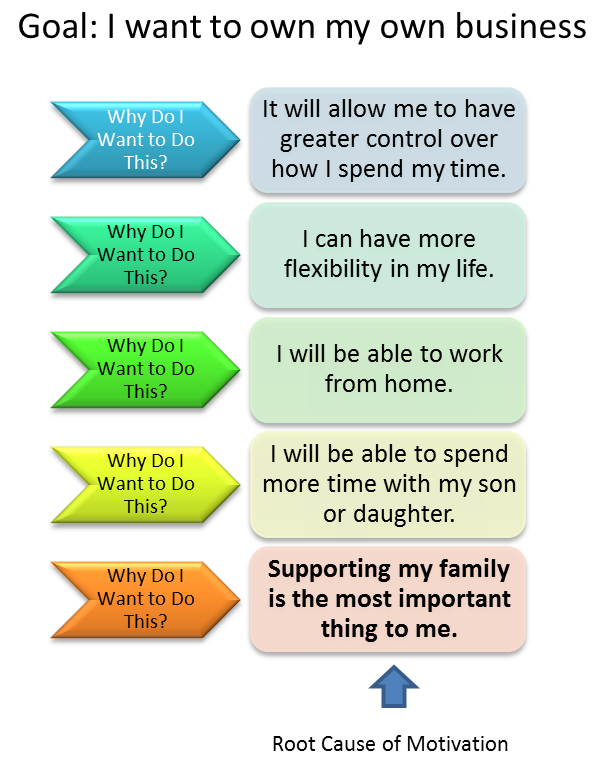

1️⃣ 5 Whys Technique

What is 5 Whys?

The 5 Whys is a simple questioning technique where you repeatedly ask “Why?” until the root cause is revealed.

📌 Usually 5 times—but it can be 3 or 7, depending on the problem.

5 Whys – Example

Problem Statement

❌ Customer received wrong invoice

| Why? | Answer |

|---|---|

| 1️⃣ Why was the invoice wrong? | Incorrect data was entered |

| 2️⃣ Why was incorrect data entered? | Operator selected wrong customer |

| 3️⃣ Why did operator select wrong customer? | Customer names look similar |

| 4️⃣ Why do names look similar? | System does not show unique ID clearly |

| 5️⃣ Why doesn’t system show unique ID? | Design requirement was missed |

✅ Root Cause

👉 System design does not enforce unique customer identification

When to Use 5 Whys

✔ Simple problems

✔ One main cause suspected

✔ Small teams

✔ Fast analysis

Limitations

❌ Can be subjective

❌ Depends on facilitator skill

❌ Weak for complex problems

2️⃣ Fishbone Diagram (Ishikawa)

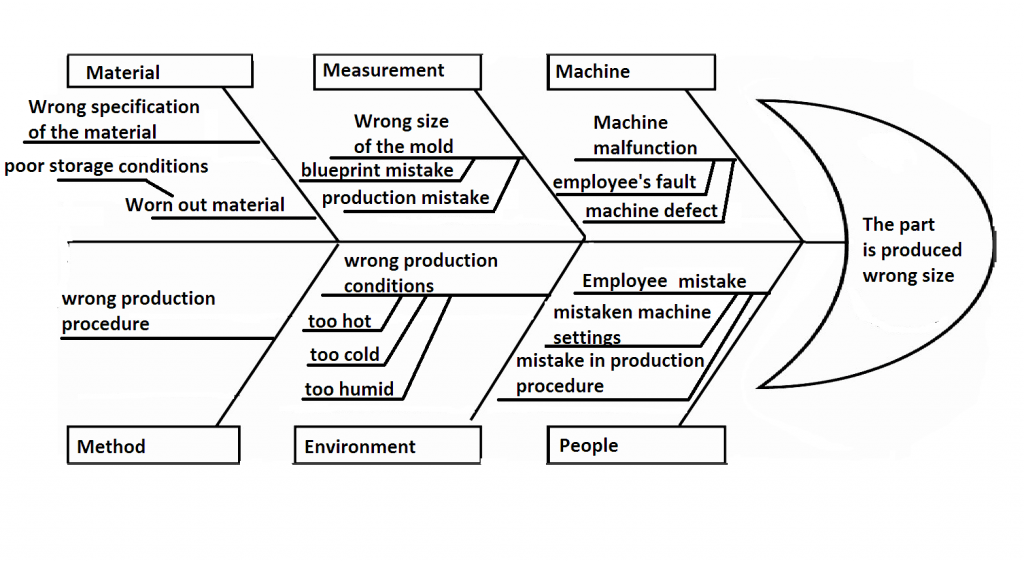

What is a Fishbone Diagram?

The Fishbone Diagram visually maps all possible causes of a problem under logical categories.

It answers:

What are all the possible reasons this problem could occur?

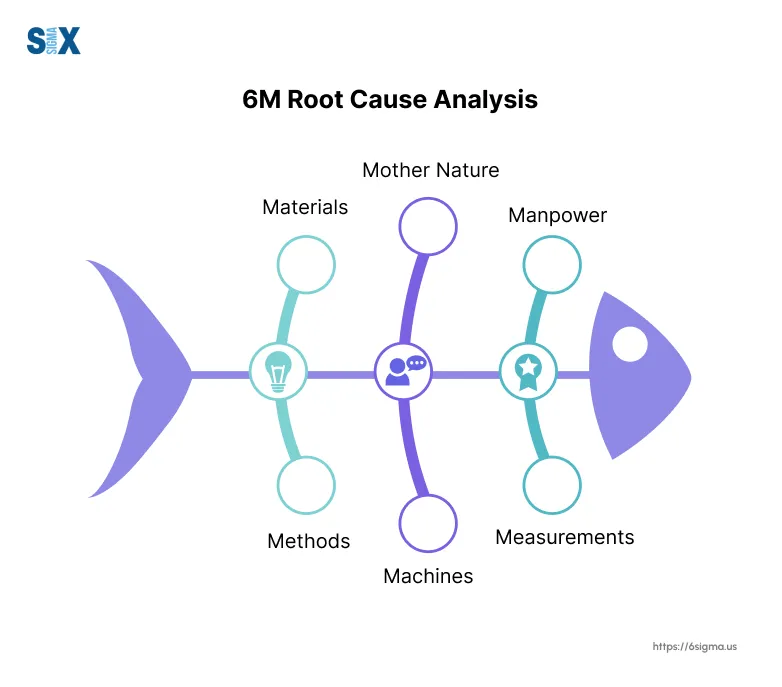

Common Fishbone Categories (6M)

Manufacturing (6M)

Man – People, skills, training

Machine – Equipment, tools

Method – Process, SOP

Material – Raw materials

Measurement – Data, metrics

Mother Nature – Environment

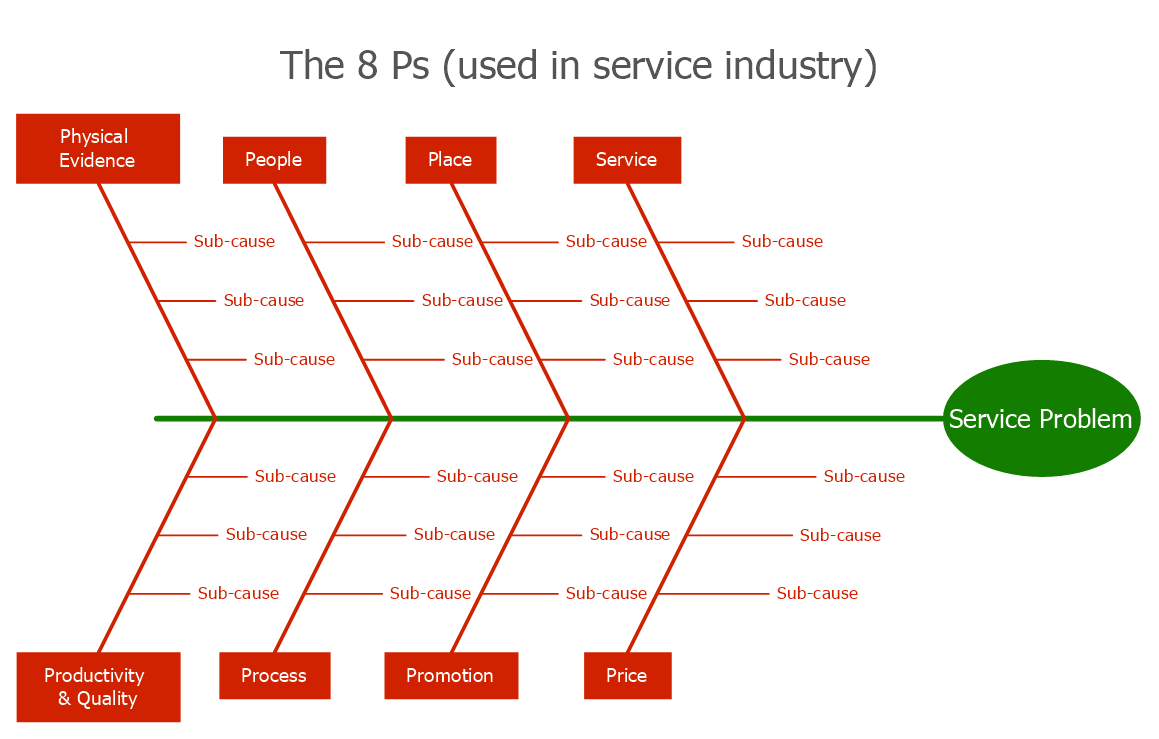

Service / IT (often adapted)

People

Process

System

Policy

Data

Environment

Fishbone – Example

Problem

❌ High order delivery delay

Possible causes identified:

People: New staff, inadequate training

Process: No standard delivery workflow

System: ERP downtime

Measurement: No delivery SLA tracking

Environment: Traffic, weather

👉 After brainstorming, data analysis confirms:

70% delays due to missing standard process

✅ Root Cause

👉 Lack of standardized delivery process

How 5 Whys and Fishbone Work Together (Best Practice)

| Step | Tool |

|---|---|

| Brainstorm all possible causes | Fishbone |

| Narrow down key causes | Data analysis |

| Drill into true cause | 5 Whys |

| Validate cause | Evidence |

| Fix permanently | Improve phase |

📌 Fishbone = Wide view

📌 5 Whys = Deep dive

Common Mistakes to Avoid ❌

Jumping to solutions too early

Stopping at symptoms

Blaming people instead of process

Not validating causes with data

Treating assumptions as facts

Lean Six Sigma Golden Rule ⭐

If you remove the root cause, the problem will not return.

If the problem returns, the root cause was not removed.

Short Summary

Root Cause Analysis in Lean Six Sigma is used in the Analyze phase to identify the true cause of defects.

Fishbone diagrams identify all possible causes, while 5 Whys drills down to the actual root cause for permanent improvement.

Comments

Post a Comment