The Kaizen Event (Rapid Improvement Event) in Lean

What is a Kaizen Event?

A Kaizen Event is a short, focused, team-based improvement effort—typically 3 to 5 days—designed to achieve rapid, measurable improvements in a specific process.

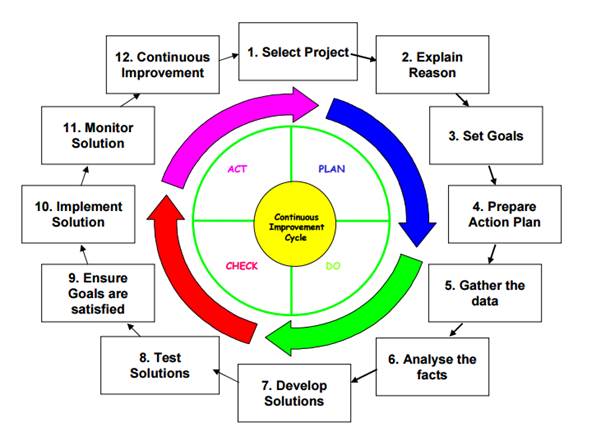

Kaizen means continuous improvement.

A Kaizen Event is improvement at high speed.

Why Organizations Use Kaizen Events

Deliver quick wins

Reduce waste (Lean focus)

Improve quality, cost, delivery, and safety

Engage frontline employees

Turn analysis into immediate action

When to Use a Kaizen Event

Use a Kaizen Event when:

The problem is well-defined

The process is localized

Solutions are known or testable

Leadership support is available

Rapid improvement is needed

❌ Not ideal for highly complex, cross-enterprise problems (use DMAIC instead).

Typical Duration & Team

Duration: 3–5 days

Team size: 6–10 members

Team makeup:

Process owner

Frontline operators

Subject matter experts

Lean facilitator

Management sponsor

Kaizen Event Phases (Day-by-Day)

Day 0 – Preparation (Before the Event)

Define problem & scope

Collect baseline data

Select team & logistics

Set clear targets

📌 Preparation determines success.

Day 1 – Understand Current State

Process walk (Gemba)

Value Stream or Process Mapping

Identify waste (TIMWOODS)

Establish baseline metrics

Day 2 – Analyze & Design

Root Cause Analysis (5 Whys, Fishbone)

Brainstorm solutions

Prioritize ideas

Design future-state process

Day 3 – Implement Solutions

Change layout / workflow

Update SOPs

Implement 5S

Train team members

Run pilot tests

Day 4–5 – Validate & Standardize

Measure results vs baseline

Adjust solutions

Standardize work

Create control plan

Final report-out to leadership

Common Tools Used in a Kaizen Event

Gemba Walk

Process Mapping / VSM

5S

5 Whys

Fishbone Diagram

Standard Work

Visual Management

PDCA

Example Kaizen Event (Simple)

Problem

❌ Order picking time too long

Baseline

Average picking time = 15 minutes

Actions during Kaizen

Rearranged layout

Implemented 5S

Reduced walking distance

Standardized pick sequence

Results

Picking time = 8 minutes

Errors reduced by 40%

Productivity improved by 30%

✅ Achieved in 4 days

Benefits of Kaizen Events

Fast results

High employee engagement

Visible improvement

Low cost

Builds continuous improvement culture

Common Pitfalls to Avoid ❌

Poor preparation

Vague problem statement

Too large scope

No follow-up after event

Management not supporting changes

Kaizen Event vs DMAIC

| Kaizen Event | DMAIC |

|---|---|

| Short-term (days) | Long-term (months) |

| Rapid improvement | Deep analysis |

| Lean-focused | Lean + Six Sigma |

| Local scope | Enterprise scope |

Success Factors ⭐

Clear goal & metrics

Strong leadership support

Empowered team

Immediate implementation

Sustained follow-up

One-Line Memory Tip 🧠

A Kaizen Event turns ideas into action—fast.

Comments

Post a Comment