Control Chart in Lean Six Sigma

Introduction

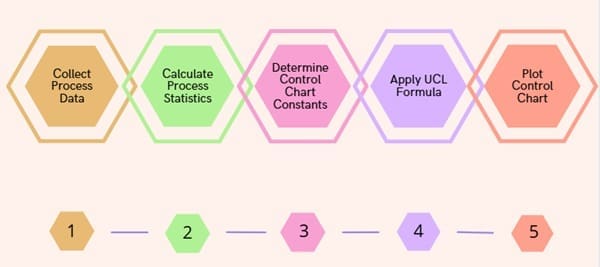

In Lean Six Sigma, a control chart is a fundamental statistical tool used to monitor process performance over time and ensure that improvements are sustained. It belongs primarily to the Control phase of DMAIC, where the focus is on maintaining process stability and preventing regression after improvements have been implemented.

A control chart helps distinguish between normal process variation and abnormal variation that requires investigation and corrective action.

What Is a Control Chart?

A control chart is a time-ordered graphical display of process data with statistically determined limits. It answers a critical question:

Is the process stable and predictable, or is something unusual happening?

A typical control chart consists of:

Center Line (CL) – the process average or mean

Upper Control Limit (UCL) – upper boundary of expected variation

Lower Control Limit (LCL) – lower boundary of expected variation

Plotted data points over time

These limits are not specification limits; they are calculated from the process data itself.

Purpose of Control Charts in Lean Six Sigma

Control charts support Lean Six Sigma objectives by:

Detecting process instability

Identifying special cause variation

Preventing defects before they occur

Sustaining gains achieved during improvement

Enabling data-driven decision making

They shift organizations from reactive firefighting to proactive process control.

Types of Variation

Understanding variation is central to control charts.

1. Common Cause Variation

Inherent to the process

Predictable and random

Requires process redesign to improve

2. Special Cause Variation

Due to unusual or assignable factors

Unpredictable

Requires immediate investigation and correction

Control charts help separate these two types clearly.

Types of Control Charts

Control charts are chosen based on data type and sample size.

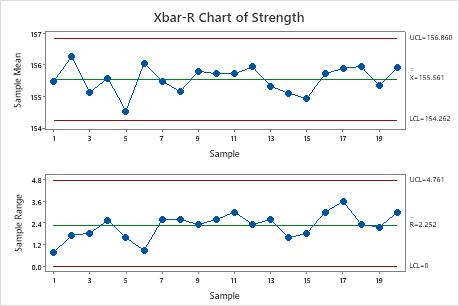

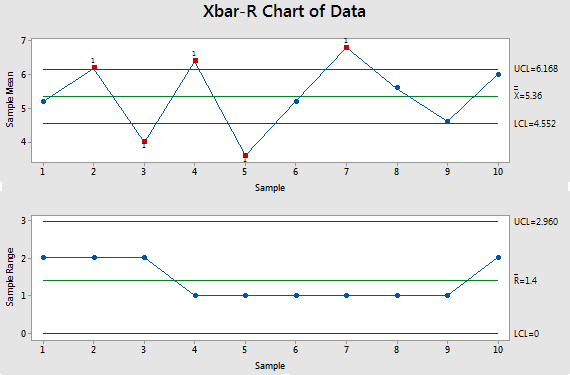

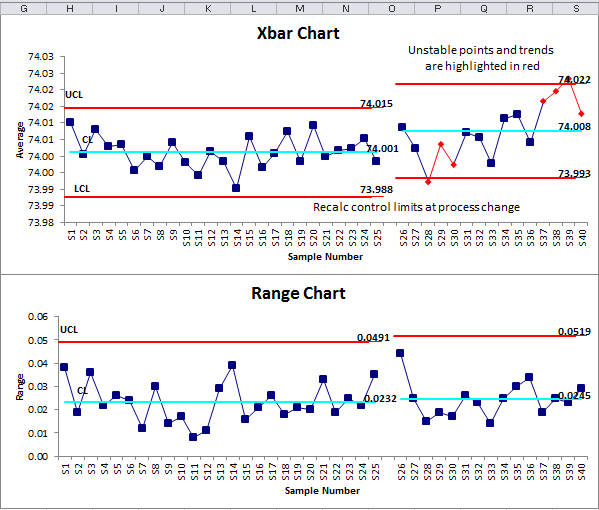

A. Variable Data Charts (Continuous data)

Used when measurements are numerical.

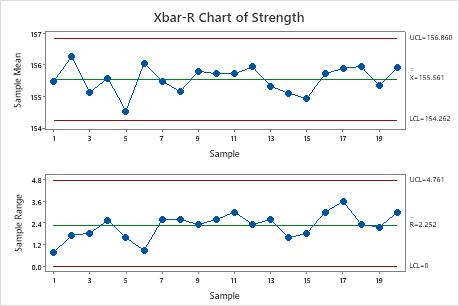

X̄ – R Chart: Mean and range (small samples)

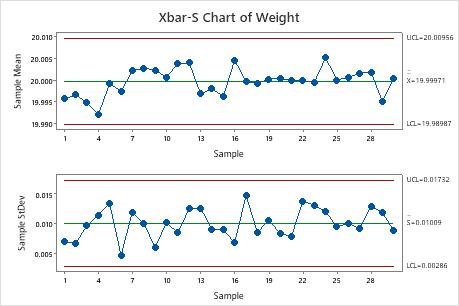

X̄ – S Chart: Mean and standard deviation (large samples)

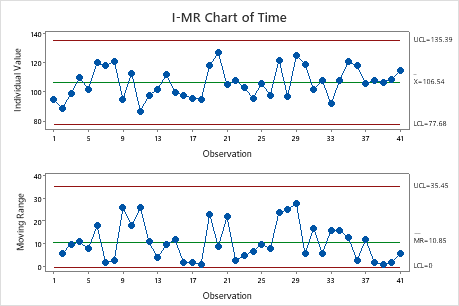

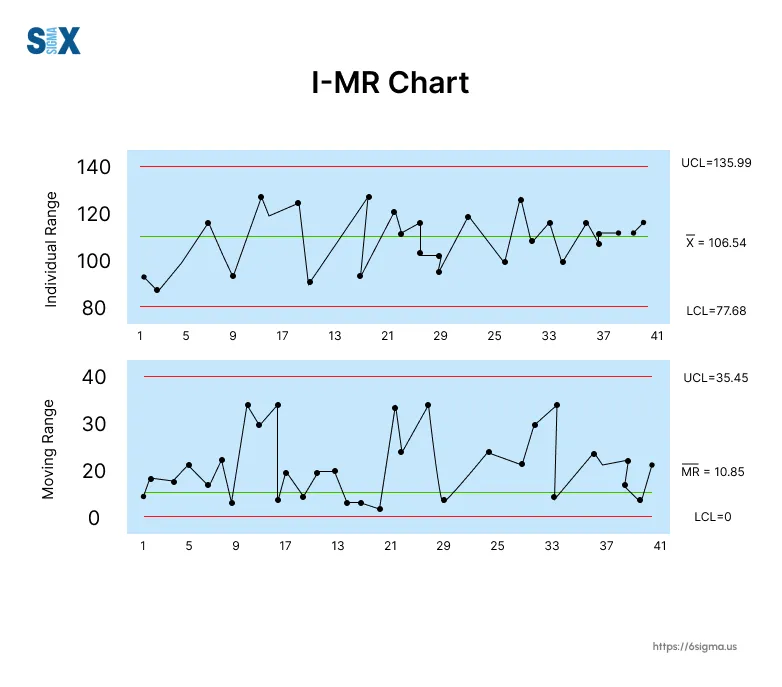

I–MR Chart: Individual values and moving range

B. Attribute Data Charts (Discrete data)

Used when data are counts or proportions.

P Chart: Proportion defective

NP Chart: Number of defectives

C Chart: Count of defects

U Chart: Defects per unit

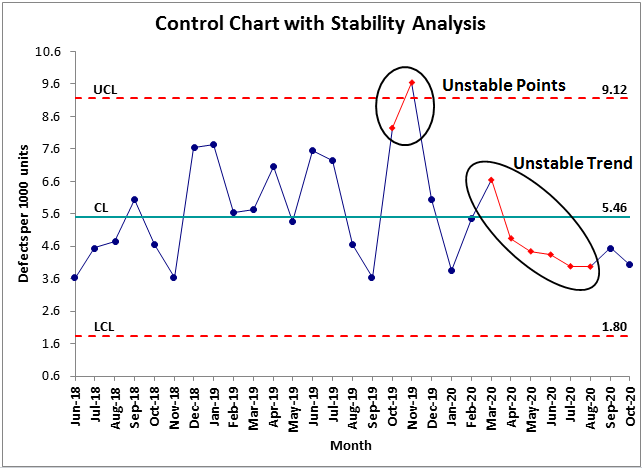

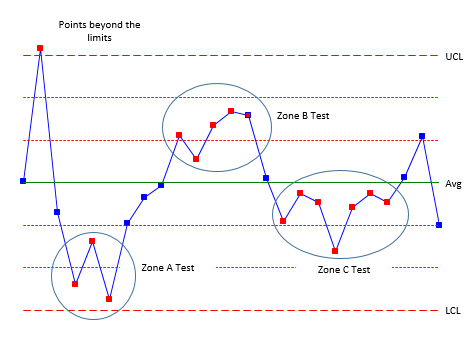

Control Chart Rules (Signals of Trouble)

A process may be out of control if:

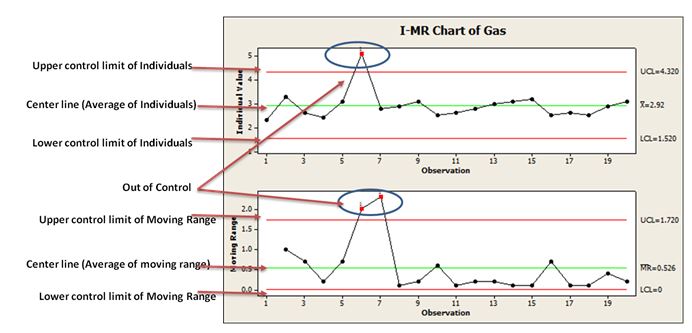

A point falls outside UCL or LCL

Seven or more points trend upward or downward

Seven consecutive points lie on one side of the center line

Cyclical or repeating patterns appear

These rules help identify hidden instability even when points are within limits.

Role of Control Charts in DMAIC

| DMAIC Phase | Role of Control Chart |

|---|---|

| Define | Understand customer requirements |

| Measure | Establish baseline performance |

| Analyze | Identify variation patterns |

| Improve | Validate improvement effectiveness |

| Control | Monitor and sustain gains |

Control charts are most critical in the Control phase, where they act as an early warning system.

Benefits of Using Control Charts

Reduces defects and rework

Improves process predictability

Enhances customer satisfaction

Supports standardization

Builds a culture of continuous improvement

Common Mistakes to Avoid

Confusing control limits with specification limits

Reacting to every data point (overcontrol)

Using the wrong type of chart

Ignoring patterns and trends

Failing to update charts after process changes

What happens when a point exceeds UCL or falls below LCL?

Let’s understand this with clear, practical examples 👇

Example 1: Point Exceeds UCL (Upper Control Limit)

Scenario

You are monitoring call handling time in a customer support process using an I–MR control chart.

Center Line (CL) = 5 minutes

UCL = 8 minutes

LCL = 2 minutes

What happened?

On Tuesday, the handling time recorded is 11 minutes, which is above the UCL.

Meaning

✔ This is special cause variation

✔ The process is out of statistical control

✔ Something unusual has occurred

Possible reasons

New employee handling calls

System outage or slow application

Very complex customer issue

No standard work followed

New employee handling calls

System outage or slow application

Very complex customer issue

No standard work followed

Action required

Stop and investigate immediately

Identify the root cause

Fix the issue

Prevent recurrence

🔴 Key point: A single point above UCL is a strong signal that the process behavior has changed.

Stop and investigate immediately

Identify the root cause

Fix the issue

Prevent recurrence

🔴 Key point: A single point above UCL is a strong signal that the process behavior has changed.

Example 2: Point Below LCL (Not Meeting LCL)

Scenario

You are monitoring fill volume in a bottling process.

CL = 500 ml

UCL = 520 ml

LCL = 480 ml

What happened?

One bottle shows 460 ml, which is below the LCL.

Meaning

✔ This is also special cause variation

✔ The process is out of control

✔ Customer dissatisfaction or defect risk

Possible reasons

Machine calibration issue

Valve blockage

Pressure fluctuation

Operator error

Machine calibration issue

Valve blockage

Pressure fluctuation

Operator error

Action required

Quarantine affected products

Check machine settings

Recalibrate equipment

Resume production only after stability

🔴 Key point: A point below LCL is just as serious as exceeding UCL.

Quarantine affected products

Check machine settings

Recalibrate equipment

Resume production only after stability

🔴 Key point: A point below LCL is just as serious as exceeding UCL.

Important Clarification (Very Common Confusion)

Control Limits vs Specification Limits

| Control Limits | Specification Limits |

|---|---|

| Based on process data | Based on customer requirement |

| Show process stability | Show acceptability |

| Used for monitoring | Used for inspection |

👉 A point within spec but outside control limits still needs investigation.

Simple Rule to Remember 🧠

Above UCL → Process behaving unusually high

Below LCL → Process behaving unusually low

Either case → ❌ Process is out of control

Above UCL → Process behaving unusually high

Below LCL → Process behaving unusually low

Either case → ❌ Process is out of control

Real-Life Analogy 🚗

Imagine driving a car:

Speed limit = Control limits

Suddenly you hit 140 km/h → exceeds UCL

Suddenly engine drops to 20 km/h → below LCL

Both are dangerous and need immediate action.

Lean Six Sigma Mindset

Do not adjust the process for normal variation.

Always investigate special cause variation.

Do not adjust the process for normal variation.

Always investigate special cause variation.

USL (Upper Specification Limit): The maximum acceptable value allowed by the customer or design

LSL (Lower Specification Limit): The minimum acceptable value allowed by the customer or design

Example 1: Manufacturing (Easy to visualize)

Scenario – Shaft Diameter

-

Required diameter = 10 mm ± 0.5 mm

Term Value USL 10.5 mm LSL 9.5 mm

Required diameter = 10 mm ± 0.5 mm

| Term | Value |

|---|---|

| USL | 10.5 mm |

| LSL | 9.5 mm |

-

10.3 mm → ✅ Acceptable (Average)

-

9.4 mm → ❌ Defect (below LSL)

-

10.6 mm → ❌ Defect (above USL)

Conclusion

Control charts are the heartbeat of Lean Six Sigma control. They transform raw data into meaningful insight, enabling organizations to maintain stable, efficient, and high-quality processes. Without control charts, improvements are temporary; with them, excellence becomes sustainable.

“You cannot improve what you do not measure, and you cannot sustain what you do not control.”

Comments

Post a Comment